CUSTOM GASKET CUTTING

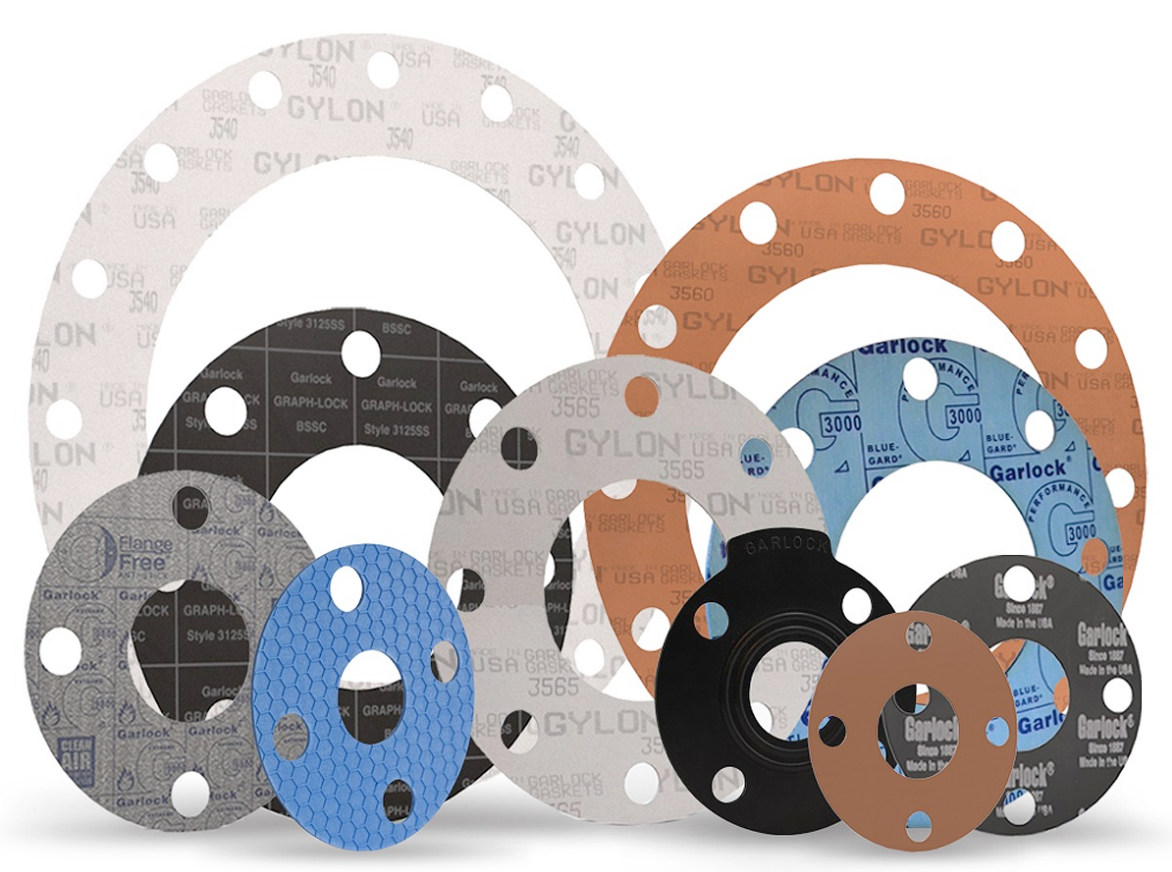

Custom Gaskets by LAKE CHARLES Rubber & Gasket

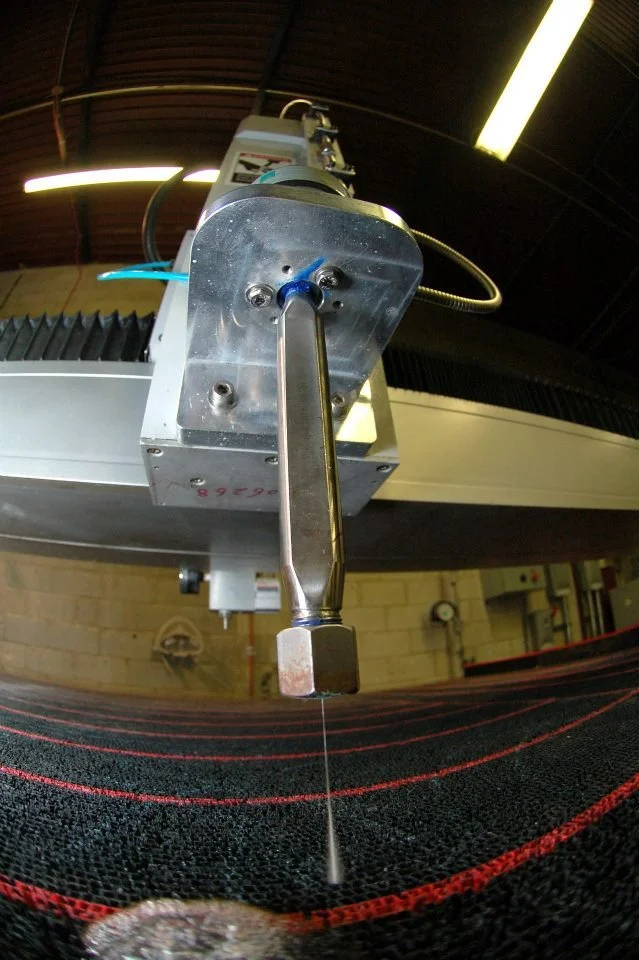

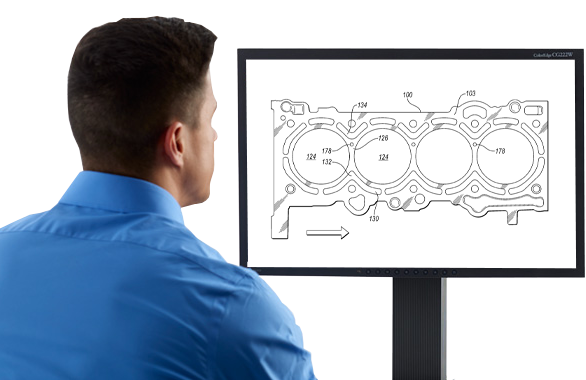

At Lake Charles Rubber & Gasket, our custom gasket cutting capabilities are elevated by the advanced ATOM Flash Cutter, delivering precision and efficiency for every project. This cutting-edge technology enables us to produce custom gaskets with complex designs and exact tolerances, tailored to meet the specific demands of a variety of industries. The ATOM Flash Cutter accommodates a broad range of materials, including rubber, foam, cork, and non-asbestos, providing clean and accurate cuts with every use. Our custom gasket services support applications across automotive, aerospace, industrial machinery, and equipment sectors. Committed to quality and innovation, Lake Charles Rubber & Gasket utilizes the ATOM Flash Cutter to supply superior custom gaskets that ensure outstanding performance and reliability, perfectly crafted to your sealing requirements.

Contact us about your project using the form below!

Applications and Benefits

Our custom gaskets are designed to provide excellent sealing solutions across a range of applications. Benefits include:

Enhanced Performance: Precise cuts ensure optimal sealing, reducing the risk of leaks and enhancing the overall performance of your equipment.

Durability: High-quality materials and accurate cutting ensure that our gaskets withstand harsh conditions and prolonged use.

Cost-Effectiveness: Custom gaskets designed to fit perfectly can reduce maintenance costs and extend the life of your equipment.

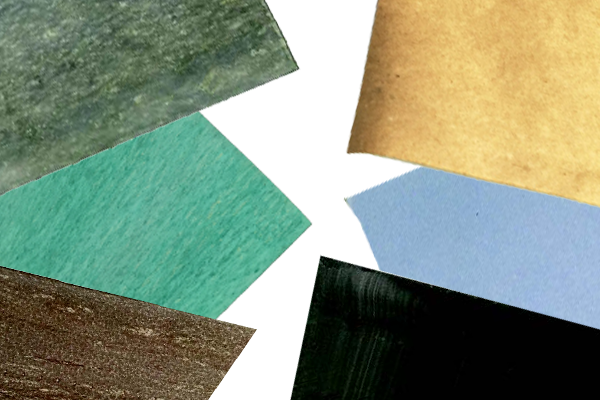

We work with a wide variety of high-quality materials, allowing us to create custom gaskets that are perfectly suited for diverse industrial and commercial applications.

QUALITY MATERIALS

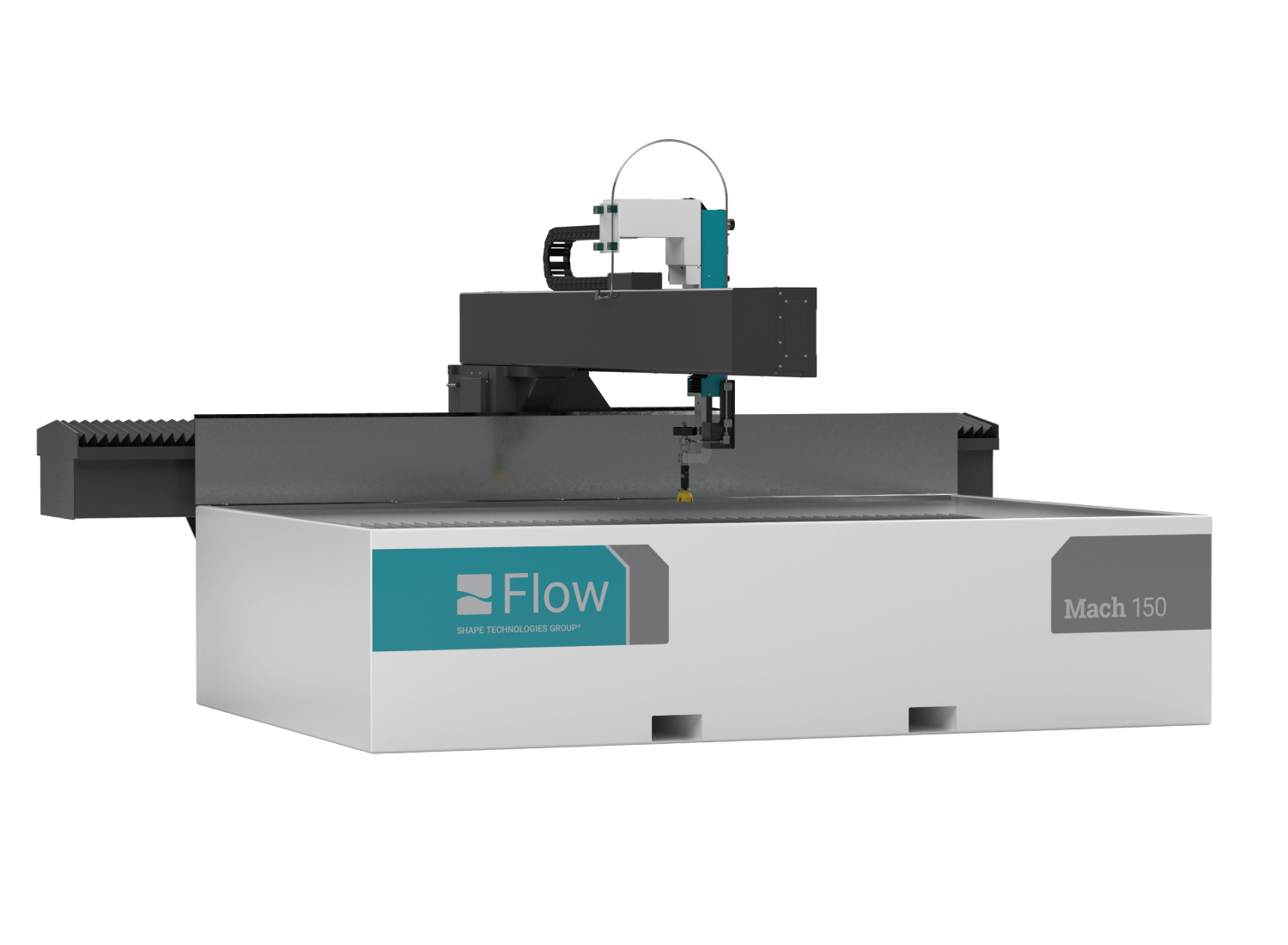

The ATOM Flash Cutter and Flow Waterjet represent the pinnacle of modern gasket cutting technology, delivering exceptional precision and consistently high-quality results in every single cut.

ADVANCED TECHNOLOGY

Our team of highly skilled professionals brings many years of valuable experience to the table, ensuring that you receive expert advice along with consistently superior customer service.

EXPERTISE & EXPERIENCE

Our efficient processes combined with advanced, state-of-the-art machinery enable us to deliver your custom gaskets promptly and reliably, ensuring that your projects stay on schedule without unnecessary delays.

QUICK TURNAROUND

Precision Shape Cutting

Lake Charles Rubber & Gasket leverages its Atom flash cutter to deliver precision die-cutting and high-throughput production for a wide range of rubber, gasket, foam, and non-metallic materials, combining speed with repeatable accuracy to meet demanding industrial specifications; the Atom flash cutter’s advanced platen design and quick-change tooling enable rapid setup for prototype runs and large-volume orders alike, minimizing lead times while maintaining tight tolerances for complex shapes, intricate internal cutouts, and multi-layer laminates, and its programmable stroke control and pressure adjustment allow delicate materials to be processed without distortion or edge fraying. Integrated quality controls and tooling diagnostics reduce scrap and downtime; operators at Lake Charles Rubber & Gasket pair the machine’s capabilities with in-house CAD/CAM and precision die-making to produce custom parts per customer drawings, from single-piece seals and O-rings to large, multi-port gaskets and custom hose end pads. The Atom flash cutter supports a broad thickness range and works effectively with nitrile, EPDM, neoprene, silicone, PTFE-encapsulated fabrics, cork, cellulose, and various foams and composites, enabling applications across hydraulics, fluid sealing, vibration isolation, gasketing for flanges, and protective padding. Secondary finishing options such as skiving, bead rolling, and post-clearing are coordinated on-site to deliver ready-to-install components, and the shop’s experience with material selection, durometer matching, and certificate traceability ensures parts perform in temperature extremes, chemical environments, and high-pressure hydraulic systems. Whether customers need single custom prototypes for validation or recurring production with kitting and inventory management, Lake Charles Rubber & Gasket’s Atom flash cutter capability is a core asset in providing fast turnaround, consistent quality, and cost-effective manufacturing solutions tailored to industrial maintenance, OEM, and repair needs.

UNBEATABLE CUTTING DIVERSITY

Lake Charles Rubber & Gasket’s Flow Waterjet capability delivers high-precision, versatile cutting for a wide range of materials and applications, enabling us to meet demanding customer specifications with speed and repeatable accuracy. Our Flow Waterjet system cuts rubber, gasket materials, plastics, composites, metals, tile, stone, and other substrates to complex profiles and tight tolerances without heat-affected zones, preserving material properties and eliminating the need for secondary machining in many cases. We support both straight and beveled cuts, intricate internal contours, slotted features, and nesting to maximize material yield, and we can process parts from prototype quantities to full production runs. Using CAD/CAM integration, we accept customer drawings, DXF/DWG files, and sample parts to program precise cutting paths, and we offer kerf compensation, part labeling, and batching for streamlined assembly and installation. Our experienced operators optimize feed rates, abrasive selection, and cutting parameters by material type and thickness to deliver smooth edge finishes and minimal taper; for thicker or harder materials we combine abrasive waterjet cutting with fixturing and multi-step processes to maintain accuracy. We also provide value-added services such as custom part inspection, protective packaging, and just-in-time fulfillment, and we can coordinate gasket fabrication, bonding, and assembly when clients require finished components rather than raw cut parts. Whether customers need emergency rush service, tight-tolerance seals for hydraulic systems, complex multi-material assemblies, or large-format cutting for industrial applications, Lake Charles Rubber & Gasket’s Flow Waterjet capability offers a reliable, low-thermal-impact solution that reduces lead times, minimizes waste, and integrates seamlessly with our broader materials and fabrication services.